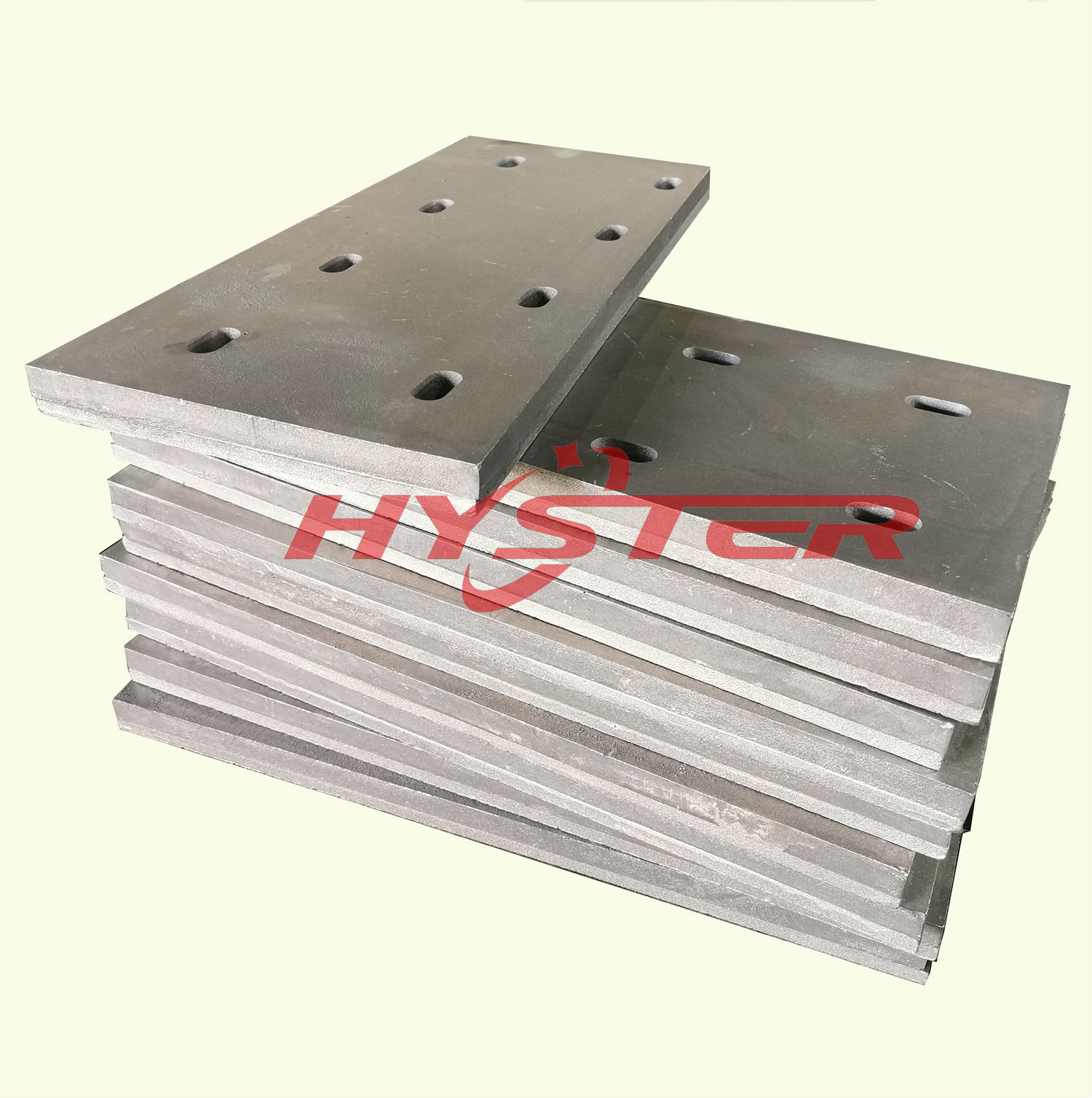

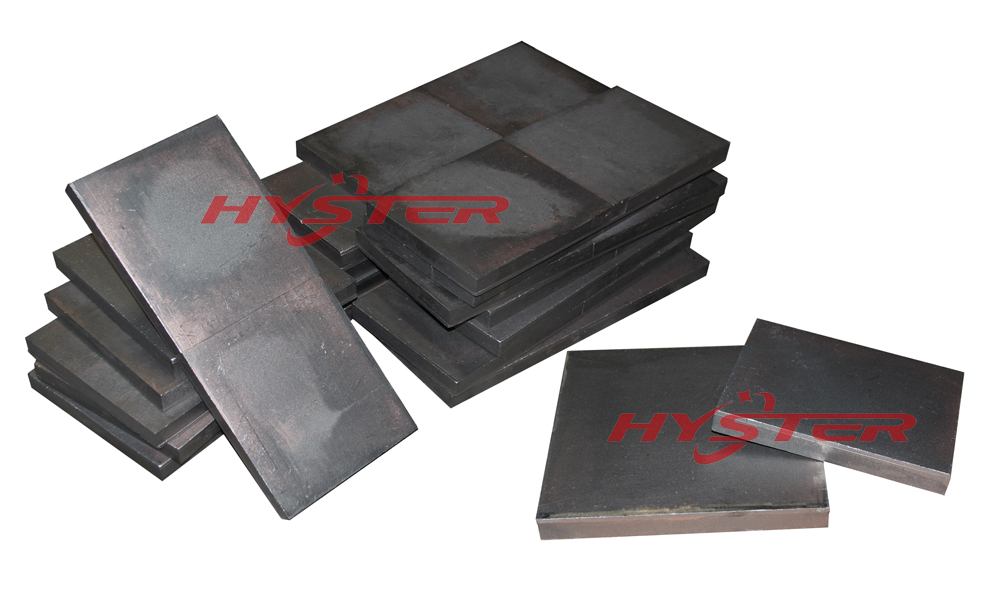

Bimetallic chrome white iron brazed wear plates

Material: Chrome white iron wear casting vacuum brazed onto mild steel base.

The smallest thickness for wear material we can make is 6mm.

Advantage:

1. Hardness: 63HRC/700BHN. The usage life is at least 2 times higher compared with overlay/hardfacing wear plates, at least 7 times longer than A.R type steels 360/400BHN. The thicker ones such as 20mm above wear, the usage life is much more longer. The wear resistance performance is the same from wear surface to the welding face.

2. Wear surface is very smooth and flat, media is not easy to stick on.

3. It can make with different shapes and sizes.

4. Better cost-efficient. Unit price is about USD5.5---USD7.5 per kilogram.

Weakness: for big sheet size, wear casting could be joint ones, not a whole sheet. For example, wear plate 1443x349x25/6mm(25mm wear, 6mm base), the wear material will be jointed with 4pcs, and mild steel base will be joint with 2pcs, joint gap is below 2mm

Suitable for use in chutes, hoppers, bins, liners, impact walls, rock boxes and a variety of other applications.

Very easy to use, no pre or post heating when welding.

Quality Guarantee

Quality Report to be submit ahead of delivery: include Metallographic Analysis & Hardness & Chemical Composition Analysis & Welding Quality(UT) & Dimensions & G65 Dry Sand/Rubber Wheel Abrasion Test & NDT Examination/LPI . We supply up to 24 month warranty on quality!

The company is certified with ISO9001:2015. We have a dedicated R&D team that can tailor various products with special requirements (such as wear resistance, corrosion resistance, impact resistance, heat resistance, etc.) and provide professional wear resistance solutions. Since its establishment, the company has carried out a lot of experiments on improving the wear resistance and composite bonding strength, various heat treatment technology on different products, and the selection of wear-resistant alloys under different working conditions. The production process and product performance are continuously optimized.

Type | Item No. | Size | Dimension(mm) | N.W.(kg) | ||||

mm | A | B | C | D | E | |||

Standard | WP 200-18 | 200x200x18 | 200 | 200 | 12 | 6 | 18 | 5.7 |

WP 200-20 | 200x200x20 | 200 | 200 | 14 | 6 | 20 | 6.3 | |

WP 300A | 300x150x20 | 300 | 150 | 14 | 6 | 20 | 7 | |

WP 250 | 250x250x20 | 250 | 250 | 14 | 6 | 20 | 9.8 | |

WP 300C | 300x300x18 | 300 | 300 | 12 | 6 | 18 | 12.7 | |

WP 300B | 300x300x20 | 300 | 300 | 14 | 6 | 20 | 14.1 | |

WP 305 | 305x150x24 | 305 | 150 | 18 | 6 | 24 | 8.6 | |

WP 300C | 300x150x25 | 300 | 150 | 19 | 6 | 25 | 8.8 | |

WP 300D | 300x300x25 | 300 | 300 | 19 | 6 | 25 | 17.7 | |

WP 445 | 445x445x25 | 445 | 445 | 19 | 6 | 25 | 38.9 | |

WP 301 | 301x200x28 | 301 | 200 | 18 | 10 | 28 | 13.2 | |

WP 294A | 294x144x30 | 294 | 144 | 20 | 10 | 30 | 10.2 | |

WP 294B | 294x294x30 | 294 | 294 | 20 | 10 | 30 | 20.4 | |

WP 300E | 300x150x30 | 300 | 150 | 20 | 10 | 30 | 10.6 | |

WP 300F | 300x300x30 | 300 | 300 | 20 | 10 | 30 | 21.2 | |

WP 372 | 372x372x28 | 372 | 372 | 20 | 8 | 28 | 30.4 | |

WP 300G | 300x300x50 | 300 | 300 | 40 | 10 | 50 | 35.3 | |

WP 300H | 300x148x50 | 300 | 148 | 40 | 10 | 50 | 17.4 | |

WP 206 | 206x203x58 | 206 | 203 | 38 | 20 | 58 | 19 | |

Trapezoidal | WPt 190 | 190x212.5x25 | 190 | 212.5 | 17 | 8 | 25 | 7.9 |

WPt 241 | 241x290.5x30 | 241 | 290.5 | 22 | 8 | 30 | 19.5 | |

Note: Studs Extra

If arc studs are required, please stipulate the size and position required.

Copyright © Hunan Hyster Material Technology Co., LTD. All Rights Reserved

Sitemap | Technical Support: